Frequently Asked Questions

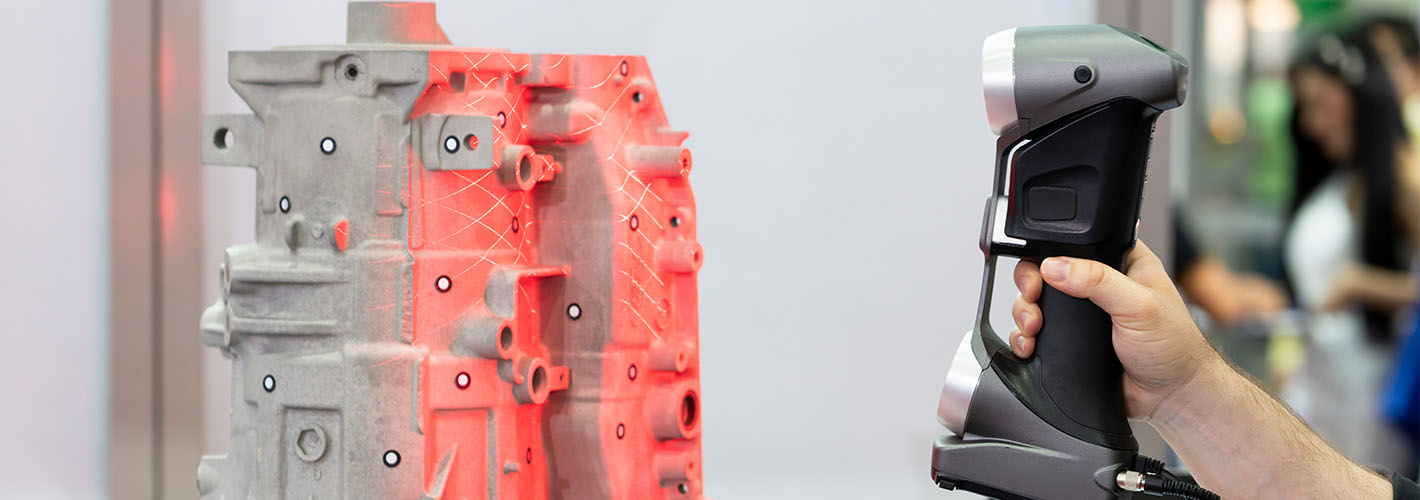

3D scanning works by first assessing the site or object and setting up the scanning equipment. The scanner then captures thousands of data points using laser beams or light patterns, creating a “point cloud” that represents the surface. This data is processed in specialised software to generate a detailed 3D model, which can be exported in various formats for use in CAD applications, simulations, or visualisations. For steel fabricators in Brisbane, such as BridgeFab, 3D scanning is particularly valuable in steel fabrication. The resulting model aids in design accuracy, planning, and documentation, significantly enhancing precision and reducing errors in construction and engineering projects.

At BridgeFab, a leading steel fabrication company in Brisbane, the duration of the 3D scanning process can vary based on the size and complexity of the site or object being scanned. For smaller areas or objects, the process may take just a few hours, while larger or more intricate sites, such as those involved in steel fabrication projects, might require a full day or more. Factors such as accessibility, the number of scanning positions needed, and the level of detail required also play a role in determining the overall time. As experienced steel fabricators, we ensure efficient and accurate 3D scanning to meet project requirements.

3D scanning can benefit a variety of industries, including steel fabrication and steel fabricators like BridgeFab in Brisbane. It enables precise measurements for construction and architecture projects, ensuring accurate site assessments and design planning. In manufacturing, 3D scanning streamlines production and quality control processes, while in engineering, it facilitates detailed analysis and prototyping. For businesses like BridgeFab, 3D scanning enhances efficiency and precision in steel fabrication projects.

Bridgefab’s 3D scanning for structural steel projects is highly accurate, typically within millimetres. Using advanced laser scanning technology, Bridgefab captures precise measurements of the job site, ensuring that steel components are fabricated and installed with minimal errors. This accuracy helps prevent misalignment, reduces material waste, and streamlines the erection process, ultimately improving project efficiency and cost-effectiveness.

Yes, 3D scanning is ideal for both new and existing structures. For new builds, it ensures precise site measurements, streamlining planning, fabrication, and installation. For existing structures, 3D scanning captures current conditions with high accuracy, making it invaluable for retrofitting, extensions, and renovations. It helps integrate new steel components seamlessly while identifying potential clashes with existing infrastructure.

Yes, 3D scanning significantly reduces the need for manual site measurements. Traditional measuring methods can be time-consuming and prone to human error, whereas 3D scanning captures comprehensive and highly accurate site data in a fraction of the time. This not only improves measurement precision but also enhances efficiency by reducing the number of site visits required for verification.

3D scanning is a technology that captures precise measurements of physical objects or environments using lasers or cameras. For structural steel projects, it offers benefits such as:

- Precision: Accurate measurements ensure precise fabrication and construction.

- Efficiency: Facilitates detailed planning, design, and clash detection, reducing errors and project timelines.

- Cost Savings: Minimises rework and site visits, leading to lower project costs.

- Enhanced Collaboration: Improves communication among stakeholders with clear, visual project data.

Overall, 3D scanning enhances project accuracy, efficiency, and collaboration in structural steel fabrication and construction.

By capturing real-time site data and creating a precise digital model, 3D scanning allows for thorough pre-fabrication planning. The resulting model can be used to virtually simulate how steel components will fit into the actual site conditions before anything is built. This reduces unexpected clashes or fitting issues during installation, saving time, material, and labour costs.

3D scanning contributes to cost savings and project timelines in several key ways. Firstly, it reduces the need for repeated site visits and manual measurements by capturing comprehensive data in a single scan, minimising labour hours and travel costs. This efficiency accelerates the initial data collection phase, allowing design and fabrication processes to commence sooner. By providing accurate measurements and detailed 3D models early in the project, 3D scanning helps identify potential clashes and design issues upfront, preventing costly rework during construction. The precise data also supports more accurate material estimates and reduces material waste. Overall, these factors combine to streamline project workflows, optimise resource allocation, and shorten overall project durations, resulting in significant cost savings and improved project timelines.

Yes, the data captured through 3D scanning can be seamlessly imported into 3D modelling software such as Tekla Structures. This allows for precise overlays of proposed steelwork onto real-world conditions, enabling early clash detection and design refinement. The integration helps structural steel fabricators improve fabrication accuracy and reduce delays during erection.

3D scanning provides a highly accurate digital representation of the job site, which can be shared across teams in real time. Engineers, architects, and structural steel fabricators can all work from the same source of truth, reducing miscommunication and design discrepancies. This collaborative clarity helps streamline planning, detailing, and approvals for complex steel structure projects.

3D scanning offers significant advantages over traditional methods in structural steel fabrication. It enhances accuracy by providing precise measurements and detailed data capture, reducing errors that commonly occur with manual methods. The technology speeds up the process by efficiently capturing comprehensive site information in a single scan, minimising the need for multiple visits and manual measurements. This capability is particularly beneficial for handling complex geometries and existing structures, allowing for accurate modelling and clash detection early in the project timeline. The detailed 3D models generated facilitate better visualisation and planning, improving decision-making throughout the fabrication and construction phases. Additionally, 3D scanning produces thorough as-built documentation that supports future renovations, maintenance, and compliance needs, ultimately leading to cost savings and streamlined project timelines.

Project Showcase

What does this mean for large construction projects?

Traditionally, a draftsperson or site engineer would be required to take manual measurements to draw-up a design layout which would then be used to determine required materials.

As any project manager would understand too well, these measurements and plans are open to human error often causing issues within the supply chain.

Contemporary steel industry innovators are now able to use advanced scanning and digital imaging technology to take a 3D snapshot of the site. This information is used by a draftsperson who then creates a complete digital representation of the worksite.

The data and information are fed to the new machinery, which cuts and processes a precise amount of material ready for transportation back to the site.

Traditionally, a small mistake in measurement could potentially cause a range of issues:

- Extending completion dates

- Blowing budgets

- Over or underestimating required materials

With new technology and machinery, human error is completely removed from the equation.

Contact BridgeFab for structural steel projects

At BridgeFab we can take care of the structural steel process from start to finish – so contact us today or call on (07) 3373 8777.