Frequently Asked Questions

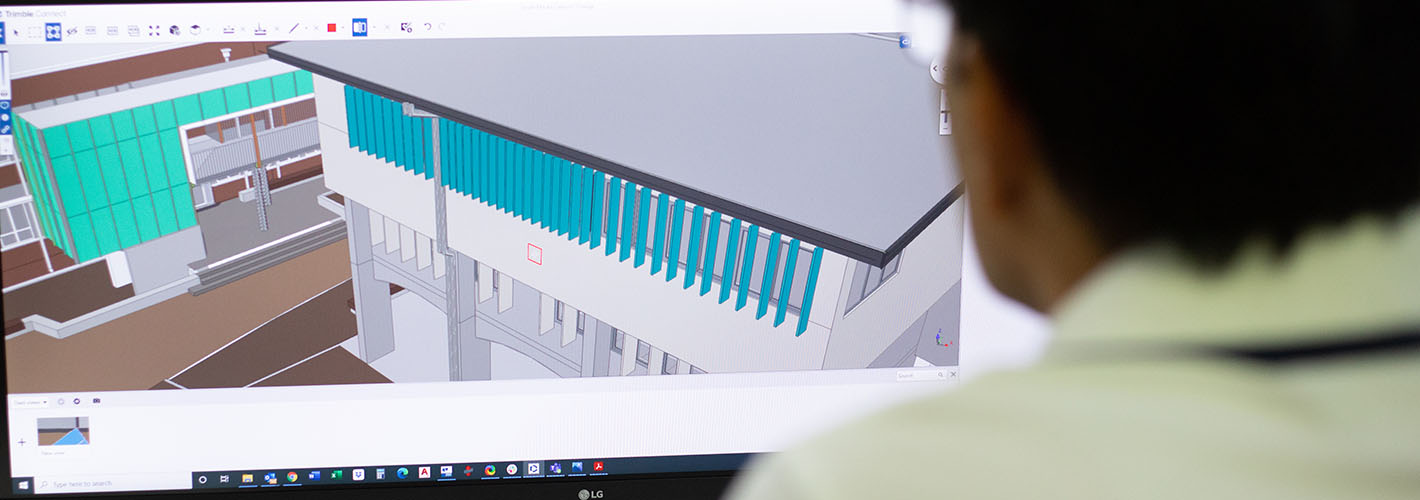

Tekla software is used for building information modelling (BIM), specifically in the field of structural engineering and construction. It is widely used for designing and detailing steel and concrete structures, such as buildings, bridges, and industrial plants. Tekla’s 3D modelling capabilities allow users to create detailed models of structures, which can then be used for visualisation, analysis, and construction planning. The software is also used for generating accurate drawings, reports, and material lists, which help streamline the fabrication and construction processes. Overall, Tekla software is a powerful tool for improving efficiency, accuracy, and collaboration in structural engineering and construction projects.

Tekla software offers a comprehensive suite of features tailored to the structural steel industry, including advanced 3D modelling capabilities for creating detailed models of steel structures; clash detection tools for identifying and resolving conflicts; automated drawing generation for fabrication and construction; accurate material takeoff functionalities; connection design tools; and robust collaboration features for sharing models and working in real-time. Additionally, Tekla integrates with other software used in the construction industry, offers project management tools for managing timelines and resources, and can be customised to meet specific project or organisational needs. Overall, Tekla software enhances productivity, accuracy, and collaboration in structural steel projects.

What sets BridgeFab apart is how we integrate Tekla Structures into every stage of the project lifecycle, from initial concept through to final erection on-site. While many fabricators use Tekla purely for drafting, BridgeFab leverages its full capabilities to drive a smarter, more efficient, and fully coordinated workflow.

We combine 3D modelling, laser scanning, automated fabrication, and on-site erection within a single streamlined process. Our team doesn’t just model in Tekla, we use it to plan material handling, coordinate with CNC machinery, manage installation sequencing, and ensure complete build accuracy.

This holistic use of Tekla, combined with our in-house expertise, CC3 certification, and investment in automation and robotics, allows us to deliver higher precision, faster turnaround times, and a more seamless client experience from start to finish.

Tekla software helps reduce project delays and rework by enabling BridgeFab to create highly accurate, data-rich 3D models of a structure before any fabrication or on-site work begins. These models help identify design issues, clashes, or inconsistencies early in the planning phase long before they can cause problems on-site.

By resolving potential errors in the digital environment, we avoid costly surprises during construction. Tekla also automatically updates drawings and reports whenever changes are made to the model, ensuring that everyone involved is always working with the latest information. This leads to better coordination, fewer revisions, and a more efficient project timeline—ultimately saving time, reducing waste, and increasing client satisfaction.

BridgeFab utilises Tekla software in its projects by leveraging its advanced 3D modelling capabilities to create detailed and accurate models of structural steel and metalwork. This includes:

- Detailed Design: Developing comprehensive 3D models for industrial and commercial steel structures, enabling precise design and planning.

- Project Visualisation: Providing clients with realistic visualisations of the finished project, aiding in design approval and decision-making.

- Fabrication Planning: Generating accurate drawings, reports, and material lists to streamline the fabrication process and reduce manual errors.

- Error Detection: Identifying and resolving potential design issues through clash detection before fabrication begins, minimising costly surprises.

- Efficient Workflow: Automating and optimising the workflow from drafting to construction, ensuring projects start sooner and are executed with greater precision.

By integrating Tekla software into its processes, BridgeFab enhances project accuracy, efficiency, and overall coordination, delivering high-quality structural solutions.

Yes, Tekla software is suitable for both small and large projects. Its versatile features and scalable capabilities make it adaptable to a wide range of project sizes. For smaller projects, Tekla can efficiently handle detailed design and documentation, while for larger, complex projects, it offers robust tools for managing intricate designs, coordinating between multiple stakeholders, and optimising fabrication and construction processes. Whether for simple structures or extensive infrastructure, Tekla provides the functionality needed to ensure accuracy, efficiency, and collaboration across all project sizes.

Tekla software offers several benefits to the structural steel industry:

- Accurate 3D modelling: Tekla allows for the creation of detailed, accurate 3D models of steel structures, enabling better visualisation and understanding of the project.

- Improved collaboration: The software facilitates collaboration between architects, engineers, and contractors by providing a centralised platform for sharing and working on project data.

- Efficient design and detailing: Tekla streamlines the design and detailing process, reducing errors and minimising rework.

- Optimised fabrication: The software generates detailed fabrication drawings and material lists, helping fabricators optimise their processes and reduce waste.

- Enhanced project management: Tekla’s project management tools help manage project timelines, resources, and costs more effectively.

- Better communication: The 3D models created in Tekla can be used to communicate design intent and construction sequencing more effectively to stakeholders.

- Cost savings: By improving efficiency and reducing errors, Tekla can help save costs throughout the project lifecycle.

Overall, Tekla software plays a crucial role in improving productivity, accuracy, and collaboration in the structural steel industry.

Tekla software is versatile and supports the design of a wide range of structures, including commercial, residential, and industrial buildings; road, rail, and pedestrian bridges; industrial plants such as power stations and refineries; communication towers and observation masts; as well as complex infrastructure like tunnels, dams, and retaining walls. It also accommodates custom and bespoke designs, including architectural features and pre-engineered modular buildings. With its detailed 3D modelling capabilities, Tekla enables precise design, analysis, and documentation across these diverse structural types.

Yes, Tekla Structures is designed for seamless integration with a wide range of construction technologies and software platforms. It supports interoperability with programmes such as AutoCAD, Revit, Navisworks, and IFC-compatible BIM tools, enabling smooth collaboration across disciplines.

Tekla also integrates directly with CNC machinery, robotic welding systems, and fabrication management software, allowing BridgeFab to automate key processes like cutting, drilling, and welding. This digital connectivity reduces manual input, minimises errors, and speeds up production.

For construction management, Tekla links with project scheduling and costing tools, supporting real-time progress tracking and better decision-making. These integrations help BridgeFab deliver projects that are more accurate, more efficient, and better coordinated from design to delivery.

Project Showcase

Steel fabrication is enhanced

3D models allow for the entire structural steel model to be fabricated with precision.

The fabrication process will utilise plans and documents linked to the Tekla 3D model, which allows for all cuts, welds, bends and more to be supported by the intelligent fabrication management software.

We have highly experienced teams

Our designers and engineers are highly specialised in designing structural steel projects using modelling software. They take an innovative and proactive approach to drive every project and ensure our workflows are as efficient, cost-effective and timely as possible.

Contact BridgeFab for structural steel projects

At BridgeFab we can take care of the structural steel process from start to finish – so contact us today or call on (07) 3373 8777.