The Benefits of Tekla 3D Modelling in Structural Steel Projects

In the dynamic world of structural steel fabrication, precision, efficiency, and accuracy are paramount. As technology continues to revolutionise the construction industry, tools like Tekla 3D modelling software have become essential for us. Tekla’s advanced capabilities offer a number of benefits that enhance the entire lifecycle of a structural steel project, from planning to fabrication to erection.

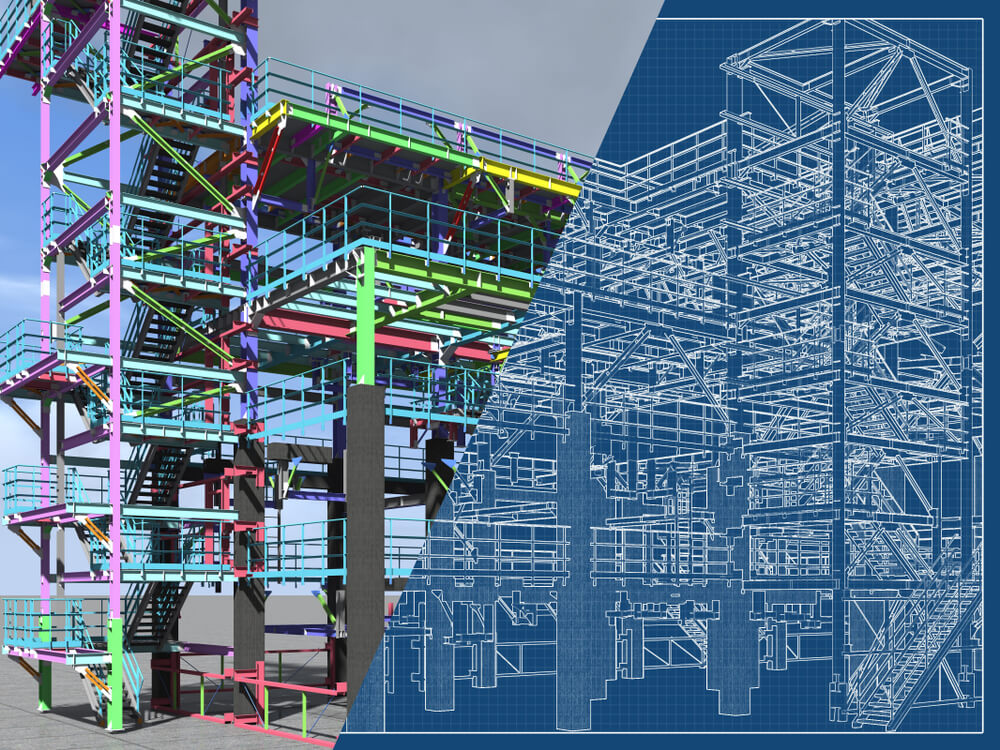

Enhanced Visualisation and Communication

One of the key advantages of Tekla 3D modelling is its ability to create fully accurate 3D detailed models of structural steel projects. These models provide a comprehensive visualisation of the finished project, allowing project managers and clients to see the structure before it is built. This visualisation enhances communication between all parties involved, ensuring that everyone is on the same page and reducing the likelihood of misunderstandings or errors.

Cost Savings and Risk Reduction

Tekla 3D modelling helps to minimise costly surprises during the construction phase. By planning projects with the software, potential issues can be identified and resolved early on, saving both time and money. The software also integrates seamlessly into BridgeFab’s systems, reducing manual work and errors. This integration means that projects can start sooner, as less time is spent on drafting and planning.

Improved Precision and Efficiency

Another major benefit of Tekla 3D modelling is its ability to improve the precision of structural steel projects. The software allows for the creation of detailed models that can be used to plan the fabrication and erection processes with complete accuracy. This minimises mistakes and ensures that the steelwork is installed efficiently and correctly.

Real-time Management and Optimisation

The benefits of Tekla 3D modelling extend beyond the planning and fabrication stages. The software also allows for real-time management of fabrication, enabling project managers to track progress and manage resources effectively. This level of control helps optimise the fabrication process, reducing waste and improving efficiency.

Enhanced Automated Workflow

One of the most significant advantages of using Tekla 3D modelling is its ability to enhance an automated workflow. The software can be used to plan which materials are required for a project, manage the fabrication and erection processes, and improve material handling. This automation not only saves time but also reduces the risk of human error, ensuring that projects are completed to the highest standards.

Speedier Project Approvals

Tekla 3D modelling speeds up project approval processes. The detailed models created with the software can be used to gain approval from clients and regulatory bodies more quickly and easily than traditional methods. This means that projects can move forward at a faster pace, saving both time and money.

Tekla 3D modelling offers a wide range of benefits for structural steel projects. From improved visualisation and communication to enhanced precision and efficiency, the software has become an indispensable tool for firms like BridgeFab. By embracing this technology, BridgeFab continues to lead the way in the structural steel industry, delivering high-quality projects that exceed client expectations.