BridgeFab have been utilising the latest advancements in technology to make the fabricating process efficient and pinpoint accurate

At BridgeFab we have always aimed to utilise the most innovative and advanced steel processing technologies and machinery.

Through new advancements, we enjoy efficient solutions, less supply chain concerns and a reduction in overall costs. So, discover how technology has helped us below.

How has technology helped the BridgeFab team?

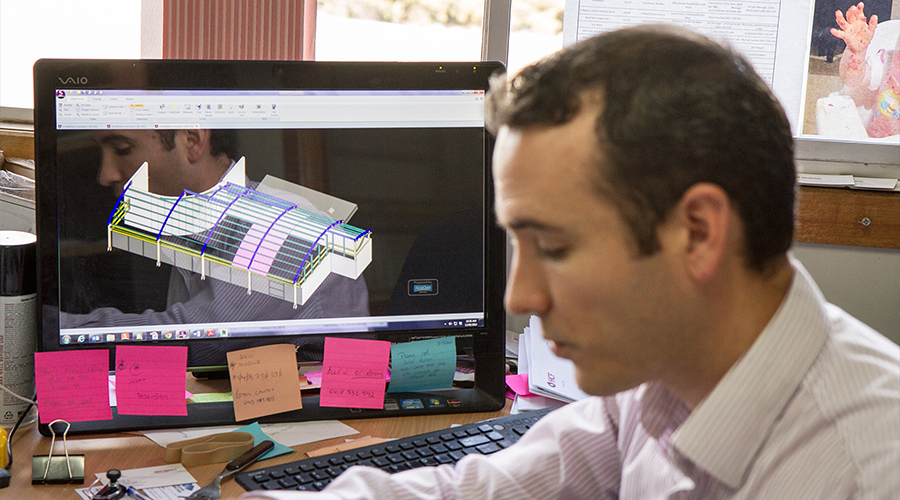

Imaging & drafting technology

Our steel processing machinery works exceptionally well with advanced drafting and imaging technologies. This means information and data can be read by our machinery and seamlessly crafted into reality with precision accuracy.

This works wonders for ensuring structural steel frameworks are perfectly fabricated.

There is no need to spend the time manually drafting the entire process up, as our technology does it. The advanced scanning and digital imaging technology we use allows us to take a 3D snapshot of the entire project site.

The 3D models of the site are used to bring a structure to life with all supported structural steel framework showcased.

Steel fabricating technology

BridgeFab uses the best technology for processing and fabricating structural steel. In fact, BridgeFab are one of the only structural steel companies in Queensland who can bend structural steel.

The technology we use, makes us experts for any project requiring steel framework, including mega structures such as buildings, as well as industrial fitouts, stairs and more.

Our technology allows us to do the following with structural steel:

- Bend

- Cut

- Shape

- Assemble

Not only has it assisted in making the drafting and steel processing process seamless, it has also reduced costs and reduced any errors in designing the structural steel wrongly.

Benefits of new technology

Upgrading to the best machinery means fabricating structural steel can be done more efficiently and cost-effectively. It also means, we can shape structural steel with complete accuracy.

What kind of projects can we work on?

As a structural steel fabricator in Queensland, BridgeFab works on both private and public projects.

Projects that are big and small, such as upgrades to existing structures, hotels, new hospital wings, warehouses, and factories – we do it all.

We complete projects from start to finish. This means we undertake the drafting and planning, to processing the structural steel, and even erecting the structure.

Get BridgeFab’s expertise

So, do you have a project in Southeast Queensland which requires structural steel? Any project, either public or private – BridgeFab has you covered.

Contact BridgeFab’s team and we can take care of the process from drafting to erecting the framework. Click here to get in touch.