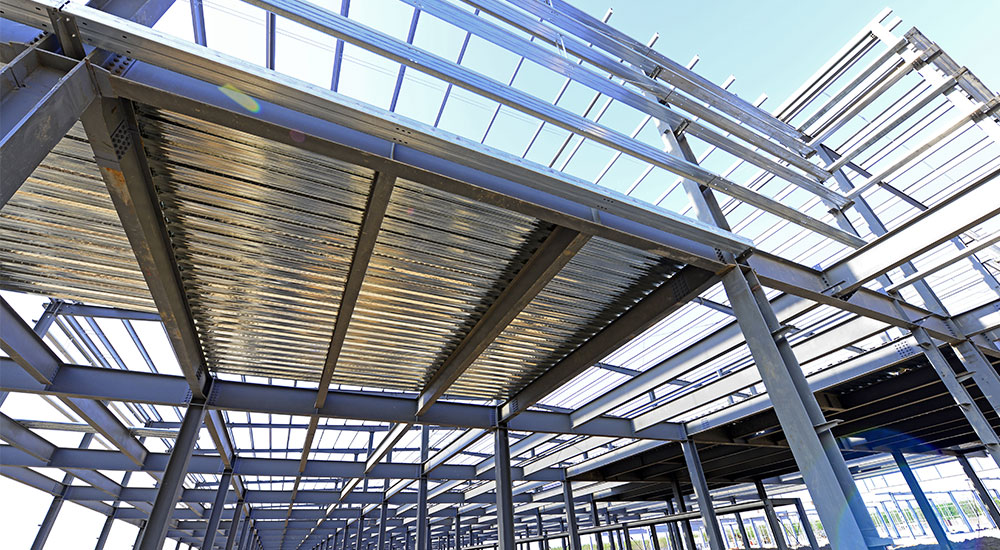

Structural steel is used as a load bearing material in large structures and has revolutionised the construction industry.

Structural steel is used in so many ways today — from the construction of buildings and bridges to transmission power lines and warehouses. It’s an incredibly diverse material, thanks to its ability to offer both strength and flexibility. But how is it actually made? And what materials are used in the process?

How is structural steel made?

Structural steel was first created in the 19th century, and the discovery revolutionised the construction industry. In fact, structural steel quickly replaced the use of most other metals used in the construction of buildings and other large structures. The main ingredient in structural steel is raw iron, which is put through a rigorous refining process in order to remove impurities. Through a heating process, other components, including carbon and manganese, are added to the iron to form good quality, high strength steel. Manganese is an important addition as it helps to improve the crack resistance and machinability of the final product, while the carbon component determines the strength and malleability of the steel.

How does steel fabrication work?

Once structural steel has been formed, it needs to be fabricated. This requires specialised skills, that include cutting, bending and assembling. During the cutting stage, steel is cut in one of three ways: shearing, chiselling or sawing, depending on the intended use of the material. The bending stage is performed by either hammering or with the use of press brakes, while the assembling stage is done by means of welding, riveting and threaded fasteners.

What is structural steel used for?

Structural steel has become the preferred material for construction because it is so well suited to the kinds of projects that are most commonly commissioned in the modern industry. Structural steel boasts a good balance of low weight and high strength, making it very versatile. Some of the benefits of using structural steel include increased speed of construction, more affordable materials and building processes, and excellent durability in the long term. Another key advantage of structural steel is that it can be designed and fabricated into almost any shape. In fact, we can take almost any preliminary designs from a client, architect or engineer and work up detailed drawings that can then be fabricated into a viable project.

How does technology help?

Although structural steel has been around for a while, the process of fabrication and erection has now been modernised with the use of technology. We use 3D scanning and drafting technology to plan an entire project before we even touch a piece of steel. Thanks to advances in modern technology, we are able to map out a project accurately and create a digitised copy of the project before we fabricate any steel. This is a major benefit, because it allows us to minimise mistakes, plus it makes the actual steelwork installation process considerably more efficient and seamless. It also gives the client the chance to make any changes to the plan before the work begins.

To find out more about our work with structural steel, please have a look here. We provide steel fabrication and erection to the Brisbane and south-east Queensland areas, and work on a wide range of projects, from residential buildings and schools to universities, hospitals, shopping centres and hotels. To take a look at some of the work we have been involved in, please browse our recent projects.

To request a quote or for more information on any of the services we offer, please don’t hesitate to get in touch. Our team is available to answer any questions you might have about the process and is happy to set up a preliminary meeting to discuss your particular project and expectations.