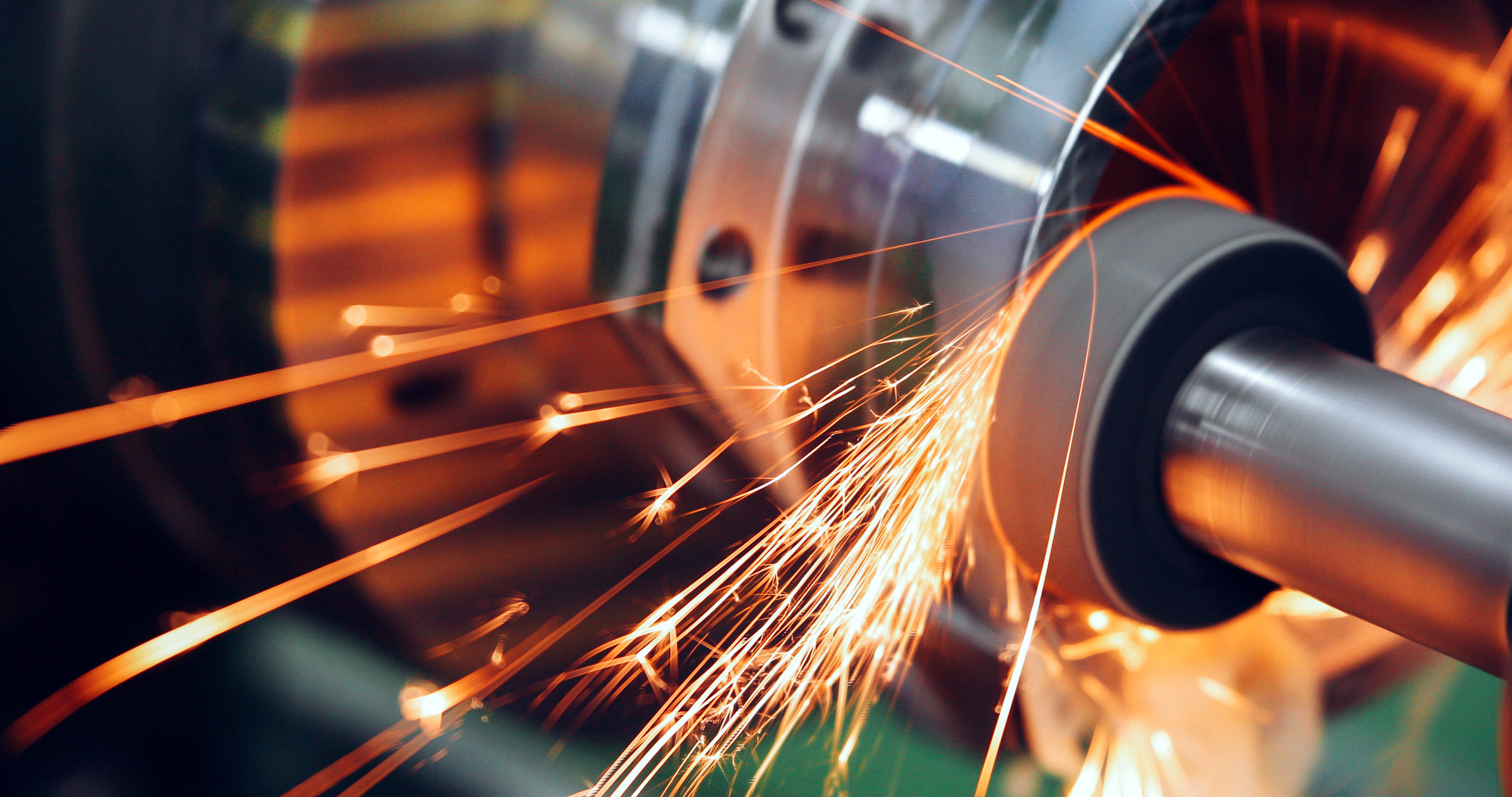

At BridgeFab, steel is processed with the use of advanced technologies and machinery.

When it comes to steel processing, we have embraced modern technologies in order to simplify the procedure, as well as reduce costs along the way. Although traditional methods certainly still have their place and remain at the foundation of the process, new advancements in the industry have played an important role in reducing inefficiencies and improving the overall method. Read on to find what modern steel processing involves, and how we can help with your next project…

What is steel made from?

Steel is made from a material called iron ore, which is a compound of iron, oxygen and other naturally occurring minerals. The raw materials that are required for steelmaking are mined and then transformed into steel as we know it by means of two different processes: the blast furnace or basic oxygen furnace method; and the electric arc furnace process. As part of these processes, the raw materials are turned into liquid iron. Both of these processes are continually evolving for improved efficiency, as well as to achieve the goal of low-emission steelmaking. When the steel has been made, it is cast using a continuous casting machine. A combination of hot and cold rolling turns the steel into coils or plates.

How is it processed?

At BridgeFab, we receive basic steel sections and plates, which we store for processing and fabrication. In order to clean the steel that we receive, we perform a process known as shot blasting in which the steel is cleaned with a high-speed stream of steel particles. This process helps to remove dirt and rust and achieves a clean finish. We then apply a prefabrication primer in order to maintain the newly cleaned surface.

When we have thoroughly cleaned the steel, it can be cut into the correct sizes and prepared for bending, drilling and shaping into structural steel beams, frames, wall panels, roof panels and more.

Why use modern technology?

The use of new technologies and machinery have made it possible to reduce project inefficiencies, as well as a range of supply chain concerns. Overall, modern technology prevents steel wastage and in doing so, reduces project costs.

In modern steel processing, advanced drafting and imaging technologies are used together with steel processing machinery. This means that information and data can be read by the new machinery and translated into reality with incredible accuracy. This makes the overall process more efficient than ever before and often reduces costs, as well as labour.

How can we help?

At BridgeFab, we offer a range of services, including steel processing. When processing steel, we make use of advanced steel processing technologies and machinery and ensure that the final product is of the highest standards. All of the steel that we receive is made from 100 percent Australian iron ore.

We are one of only a few advanced steel processing providers in Australia and have invested in new state-of-the-art technology and machinery. Our team is available to discuss the benefits of our modern steel processing techniques with you and is happy to address any questions that you might have.

If you would like to find out more about our steel processing services, please have a look here.

To arrange a consultation with us or to request a quote, please don’t hesitate to get in touch or give us a call on (07) 3373 8777.

Besides steel processing, we also offer a range of other services. These include 3D detailing; 3D scanning; steel fabrication; erection of steel; assistance with new buildings; and shopping centre extensions. To find out more about our capabilities, please have a look here. We are experts in the field and have been providing services to the Brisbane and southeast Queensland community for many years.