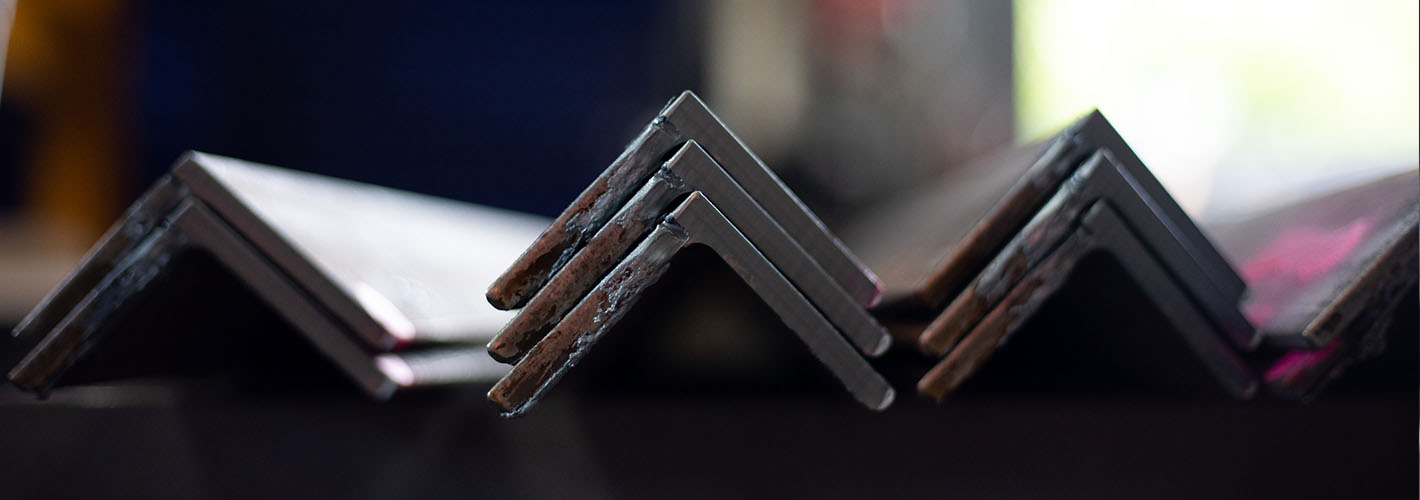

There are many different types and grades of steel.

Steel is highly versatile, durable and strong, but did you know that there are actually over 3000 grades of the material? The grade of steel is determined by how much carbon it contains, as well as what other alloys it contains and the way in which it is processed. Read on to find out more about the different types of steel, and how the grading system works.

What types of steel are there?

Steel, which is made up of iron and carbon, is usually categorised into one of four categories: carbon, alloy, stainless and tool. Carbon steel typically contains only trace amounts of any elements besides iron and carbon, and is the most common type of steel. Carbon steel can be further categorised into low, medium or high carbon steel, depending on its carbon level.

Alloy steel, on the other hand, contains a number of elements, including copper, nickel, aluminium and chromium. These alloying elements have an impact on the strength and corrosion resistance of the metal.

Stainless steel, which is well known for its resistance to corrosion, typically contains between 10 and 20 percent chromium. Stainless steel is widely used in a range of applications, including food processing equipment, pipes, and medical equipment.

Tool steels are often used in drilling and cutting equipment. They contain a number of elements that contribute to characteristics like durability and heat resistance.

What are the grades of steel?

Steel is categorised according to the way in which it is processed, as well as its unique set of properties and potential uses. Steel grading systems are helpful for a range of professionals, from engineers and architects to scientists and government bodies as they provide a level of consistency and quality when it comes to choosing and regulating materials. With the correct grading standards in place, it is possible for manufacturers to ensure proper processing of quality materials.

When it comes to the grading of steel, there are a number of systems in place. The SAE grading system involves the use of a four-digit number to classify materials — the first two digits identify the type of steel and the concentration of alloying elements, while the last two digits are an indication of the carbon concentration.

Another grading system that is used is known as the ASTM grading system. This system assigns letters for both the metal’s overall category, as well as the specific properties of each metal.

How can we help?

At BridgeFab, we specialise in the fabrication and processing of steel. Besides steel fabrication and processing, we provide a number of services, including drafting and detailing, as well as the erection of quality steel components for a range of industries and jobs of all types and sizes. In fact, our team is able to take a project from start to finish — from the preliminary meetings and planning stage, all the way through to the installation and final inspection. To find out how our seven-stage process works, please have a look here.

If you are interested in finding out more about our services and would like to arrange a consultation, please don’t hesitate to get in touch. We are a family-owned business and pride ourselves on delivering high-quality products and services. We provide services to clients in Brisbane and south-east Queensland — if you would like to see some of the projects we have worked on in these areas, please have a look at our showcase page here.