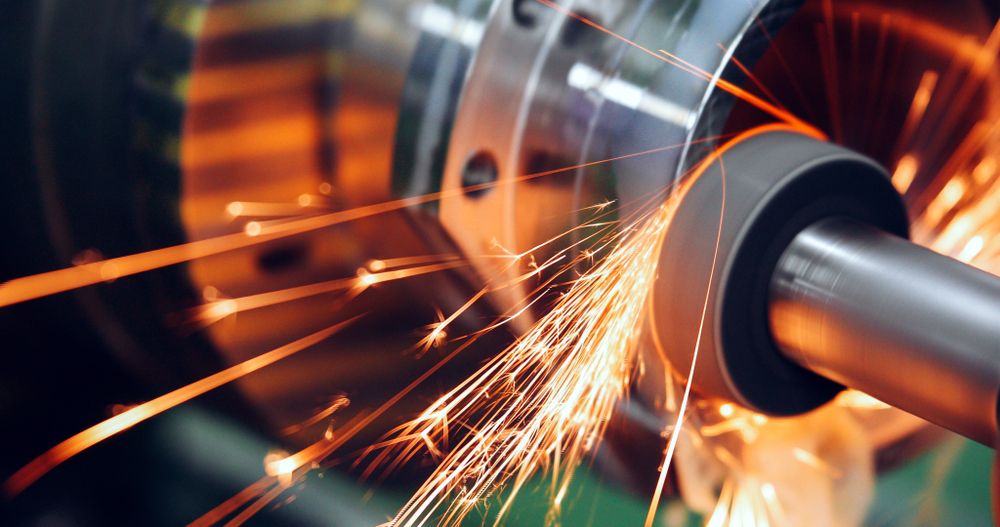

Steel is processed with the use of modern technologies and machinery.

Thanks to advancements in the industry, steel processing has progressed considerably in recent years. Now, technology and machinery make the process much more efficient and advanced than before. Here’s how the process works, and how we can help with your steel needs.

How do we use technology?

We use modern steel processing machinery, which allows us to work with advanced drafting and imaging technology. New machinery works by reading information and data and translating it into reality, thus cutting down on inefficiencies.

Although we draw on many of the old traditional (and reliable) methods, new technology has allowed us to streamline our processes significantly, prepare materials with greater accuracy, reduce inefficiencies and costs, and reduce many supply chain concerns.

What is the impact on big projects?

In the past, a draftsperson or a site engineer would take manual measurements at a project site in order to draw up a design layout. This layout would then be used to determine the required materials for the project itself. Now, thanks to the use of modern technology, we are able to use advanced scanning and digital imaging to create a 3D snapshot of the project site. This image can then be used by a draftsperson to create a detailed digital representation of the worksite.

Data and information are fed to the modern machinery, which means that a precise amount of required material can be accurately calculated. This way, there is no room for human error, and the risk of over or underestimating the required materials is minimal. This allows us to stick to both budgets and timelines, making the entire process run smoother.

How does technology benefit steel processing?

The main benefit of modern steel processing is that it simplifies the supply chain considerably. As a steel processing company, we are now able to complete a job from start to finish — this includes the drafting, processing and erection phases of a project.

Modern technology and new steel processing methods have also allowed us to reduce our costs, which in turn saves our clients money. We are able to reduce the likelihood of human error, as well as labour costs, which means that we can offer very competitive prices.

Another benefit of modern and advanced steel processing is that we can work on a broad range of projects. As well as large-scale construction, we can also assist with boutique and architectural work and design. In fact, we have been involved in a wide variety of projects, from medical centres and university buildings to shopping centre expansions and unit developments.

At BridgeFab

If you are interested in finding out more about our steel processing methods, we encourage you to get in touch. To request a quote, complete our form here and we will do our best to get back to you within two working days.

As a family-owned business based in Brisbane, we look forward to meeting you and helping you with your project. We are proud to have embraced modern technology, including advanced robotics and automation, which allows us to deliver excellent results when it comes to steel fabrication and erection.

To find out more about our business and the services that we offer, please take a look here. We offer a wide range of services and have worked on many projects over the years. If you are interested in seeing some examples of the projects we have been involved in in the Brisbane and south-east Queensland areas, please take a look at our showcase page where you’ll see some pictures of our work — browse through and let us know if you would like more details about any of the project specifics.